Port Saver - superior operational lifetime, considerable cost savings

Nowadays, no development, production, testing, or quality control department that deals with RF signals on coaxial lines can afford to dispense with state-of-the-art high-precision equipment. It’s essential to use vector network analyzers (VNAs) in particular with high-precision connectors, terminations, and adapters.

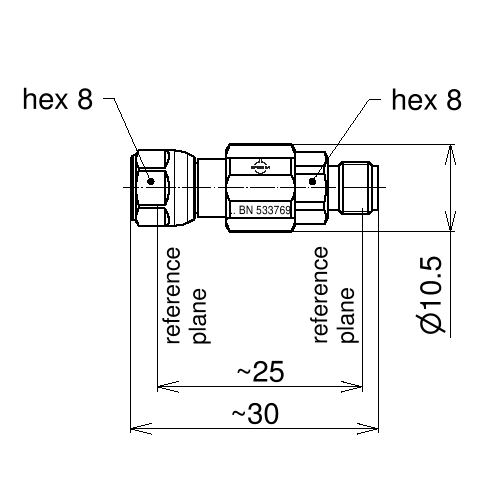

But the operational lifetime of the plug connectors used for testing is limited. Especially in connection with very high-quality testing equipment, the frequent need to replace worn-out connectors is a major cost factor. Hence a 3.5 mm male to 3.5 mm female precision adapter provides superior operational lifetime, thus generating considerable cost savings.

The 3.5 mm male to 3.5 mm female precision adapter has a characteristic impedance of 50 Ω. It is characterised by very low VSWR and attenuation values as well as best intermodulation properties in the entire operating frequency range from DC to 32 GHz.

This product has gold-plated connections and is based on the better quality classes of the IEEE, ICE standards with regard to lower tolerances. SPINNER also uses the term ‘precision’ here to emphasize the suitability for exceptionally high-precision measurements.

3.5 mm coax connectors can be used up to 33 GHz and have low manufacturing tolerances. They are designed for many mating cycles It has an air dielectric interface and closely controlled center conductor support bead providing mechanical interface tolerances similar to hermaphroditic connectors. A 3.5 mm coaxial interface can be mechanically mated with 2.92 mm and SMA connectors, but the connection creates a signal reflection that must be considered.

SPINNER RF measurement components meet highest standards

SPINNER has set new standards of accuracy with this product line, which includes a large family of coaxial test equipment with outstanding electrical and mechanical attributes for use in laboratory and production environments.

For the production SPINNER applies extremely high standards regarding quality, engineering, materials and manufacturing e.g. DIN EN ISO 9001 - Quality Management, DIN EN ISO 14001 - Environmental Management and ISO 50001:2011 - Energy Management. This enables us to offer port savers with the best possible performance and lowest possible intermodulation (Low PIM).