Introducing Data and Power Transmission Rotary Joints for Amusement Rides: Precision, and Seamless Connectivity

Unlock the true potential of fun rides with our cutting-edge data and power transmission rotary joints. With our innovative solutions, you can seamlessly transmit data and electrical power between rotating and stationary components, evolving the way fun rides operate and ensuring an unforgettable experience for riders in

- carousels,

- autodromes,

- air and boat swings,

- Ferris wheels,

- roller coasters,

- ghost trains,

- free-fall towers,

- and many more.

Our data and power transmission rotary joints cater to a wide range of critical applications within amusement rides - stationary in amusement parks or mobile for fairs or events. From ride control and safety systems to sensor data collection, audio and music systems, video and lighting displays, communication and interactivity, and even telemetry and maintenance monitoring, our rotary joints provide the robust and reliable connectivity required for these advanced functionalities:

- Ride Control and Safety Systems: Fun rides often incorporate sophisticated control systems to manage the operation, speed, and safety features of the ride. Data transmission through rotary joints enables real-time communication between the rotating and stationary parts of the ride, allowing for seamless control and monitoring of various ride parameters.

- Sensor Data Collection: Fun rides may utilize sensors to gather data on factors like ride speed, acceleration, temperature, and position. Rotary joints with data transmission capabilities enable the transfer of sensor data from rotating components to stationary control systems, facilitating analysis, monitoring, and adjustment of ride performance.

- Audio and Music Systems: Many fun rides feature audio and music systems to enhance the overall experience. Rotary joints with data transmission capabilities can transmit audio signals from a stationary source to rotating speakers or audio devices, ensuring continuous and synchronized playback of music, sound effects, or ride narration.

- Video and Lighting Systems: Fun rides often incorporate video displays or lighting effects to create captivating visuals. Rotary joints with data transmission enable the transfer of video signals or control signals for lighting systems from a stationary control system to rotating displays or lighting elements, enabling dynamic and immersive visual experiences.

- Communication and Interactivity: In certain interactive fun rides, communication between riders and stationary control systems may be necessary. Rotary joints with data transmission can facilitate two-way communication, allowing riders to interact with the ride or participate in interactive elements while maintaining a continuous data connection.

- Telemetry and Maintenance Monitoring: Rotary joints with data transmission capabilities can be used to transmit telemetry data from rotating components to stationary systems. This enables continuous monitoring of ride performance, health diagnostics, and predictive maintenance, ensuring timely intervention and reducing downtime.

These use cases demonstrate how data transmission through rotary joints enhances the functionality, safety, and overall experience of amusement rides. By enabling seamless communication between rotating and stationary components, these joints play a crucial role in integrating various systems and technologies within the ride.

Experience the ultimate control and precision with our high-speed data transmission capabilities. With our reliable and efficient data transmission, you can achieve unmatched synchronization and responsiveness, creating captivating experiences for riders.

Overcome challenges, embrace success

We understand the unique challenges faced by technical engineers for modern and future fun rides. That's why our rotary joints are engineered to surpass expectations and tackle common hurdles head-on. We address challenges such as reliable data transmission through rotating joints, efficient power delivery, signal interference and noise management, mechanical wear and tear, and compliance with safety standards. By providing robust construction, advanced shielding techniques, and efficient power transfer mechanisms, we ensure optimal performance and longevity. By choosing SPINNER’s rotary joints, you unlock a world of advantages. Our solutions empower you to elevate fun rides to new heights, captivating riders and leaving them with memories they'll cherish.

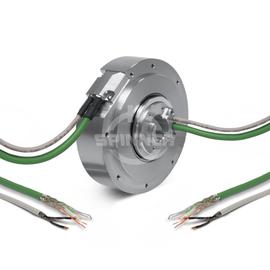

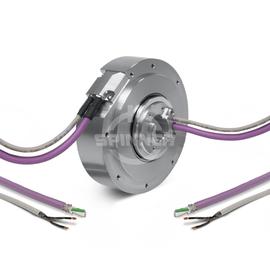

In order to transmit signals through rotating elements of a fun ride, special slip rings are often used. They consist of two main parts: a stationary brush assembly and a rotating ring assembly.

There are several alternatives to slip rings that can be used to transmit signals and power through rotating elements. One alternative is contactless rotary joints, which use wireless or optical technology to transfer data and power across the rotating joint.

Here are some examples of contactless rotary joints:

- Wireless power transfer (WPT): WPT technology uses magnetic fields to transfer power wirelessly across a small gap between a stationary coil and a rotating coil. This technology can be used to power small electronic devices in the rotating part.

- Fiber optic rotary joints (FORJ): FORJ technology uses optical fibers to transmit data across a rotating joint. The optical fibers are connected to a stationary connector that transmits the data to the control system.

- Inductive rotary joints: Inductive rotary joints use electromagnetic induction to transfer power and data across a rotating joint. These joints can be used to power motors and other electrical devices in the rotating part.

- Capacitive rotary joints: Capacitive rotary joints use capacitive coupling to transfer power and data across a rotating joint. These joints can be used to power sensors and other low-power devices in the rotating part.

Each of these technologies has its own advantages and disadvantages, and the choice of technology depends on the specific application and requirements. For example, wireless power transfer may be suitable for powering small devices but may not be able to provide enough power for larger motors. Similarly, fiber optic rotary joints may provide high-speed data transfer, but may be more expensive than other options.

Partner with the Experts

Our team of experienced engineers and industry experts is dedicated to delivering state-of-the-art solutions tailored to your unique needs. We prioritize durability, reliability, and compliance with stringent safety standards, ensuring your complete peace of mind. With our comprehensive support and superior products, you can confidently create captivating fun rides that surpass expectations.

Don't settle for less when it comes to data or power transmission in fun rides. Experience the power, precision, and seamless connectivity of our rotating solutions. Join the ranks of leading technical engineers who trust our solutions to deliver extraordinary experiences. Contact us today to embark on a new era of fun ride innovation.

- High performance: SPINNER rotary joints offer low insertion loss or excellent VSWR (Voltage Standing Wave Ratio) performance, ensuring reliable transfer of electrical power, radiofrequency or optical signals with minimal power loss or signal distortion.

- Durability and reliability: SPINNER rotary joints are designed and manufactured to withstand harsh environmental conditions, which includes exposure to dust, moisture, saltwater corrosion or high temperatures, and frequent use, ensuring reliable and long-lasting performance. They are designed to withstand the constant rotation and the stresses associated with fun ride operation.

- Minimal maintenance requirements: SPINNER rotary joints require minimal maintenance and are designed for easy repair and replacement, reducing downtime and maintenance costs.

- Wide range of options: SPINNER offers a wide range of rotary joint options, including different sizes, frequencies, technologies and (rf, fiber optics, Ethernet, …) and power handling capabilities, allowing for greater customization and flexibility in design.

- Integration with automation systems: SPINNER rotary joints can be integrated with automation systems for remote monitoring and control, allowing for more efficient and streamlined operations.

SPINNER rotary joints offer several advantages, including a wider range of options, higher electrical performance, and better durability and reliability. Additionally, SPINNER's focus on customization and flexibility allows for more tailored solutions to meet the specific needs of fun rides.